200以上 angularity gauge 757440-Hole angularity gauge

132 MMB Basics Gauge Example and RMB 133 MMB Basics Gauge Example at MMB 134 MMB Basics Datum Shift and Use 272 Angularity Uses and Key Notes 273 Angularity Measurement and Control R27 Review Handout Angularity Q27 Angularity Quiz 9 Section 7 Profile TolerancesNukeSafe™ Nuclear Gauge Emergency Response Kit Covid Safety Key FREE w/ $499 Purchase or Higher Safety First Wallet Burn Card Zetex HighTemp Gloves 23"Length, Pair HighTemp Gloves, 14" Zetex Coarse Aggregate Angularity Apparatus $Use the feeler gauge to measure under each corner of the foot, paying attention for bent or cracked feet Once the gaps are filled, retighten all of the hold down bolts Use a diagonal pattern to tighten, from one corner to its diagonal opposite Hand tighten at first, then work your way around the machine in the same pattern, tightening each

Measuring Angularity Measuring With Datums Orientation Tolerance Gd T Fundamentals Keyence America

Hole angularity gauge

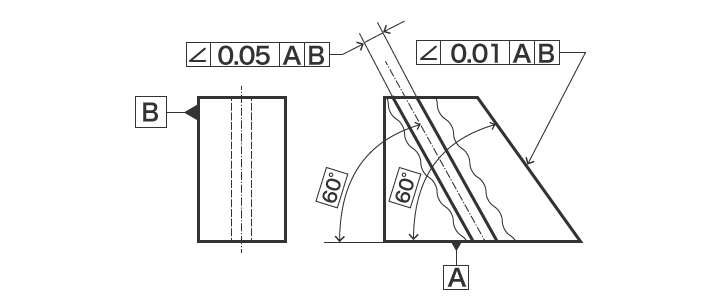

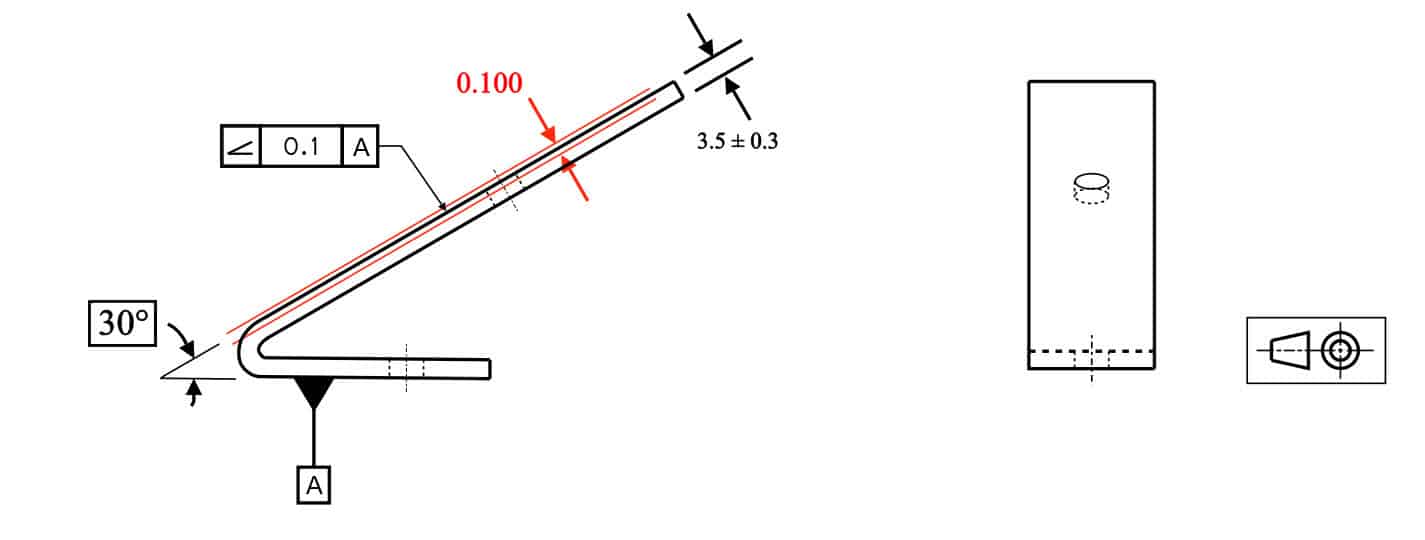

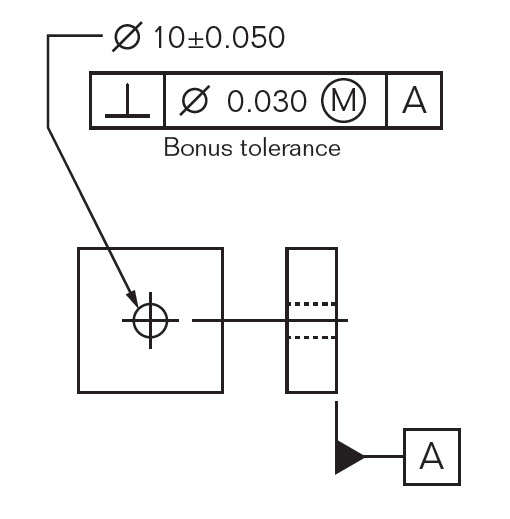

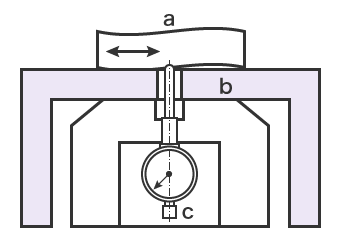

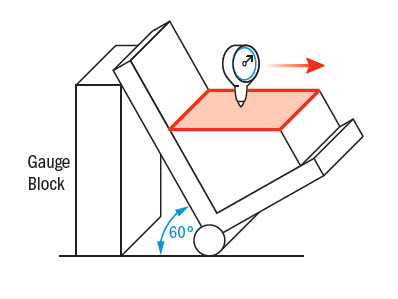

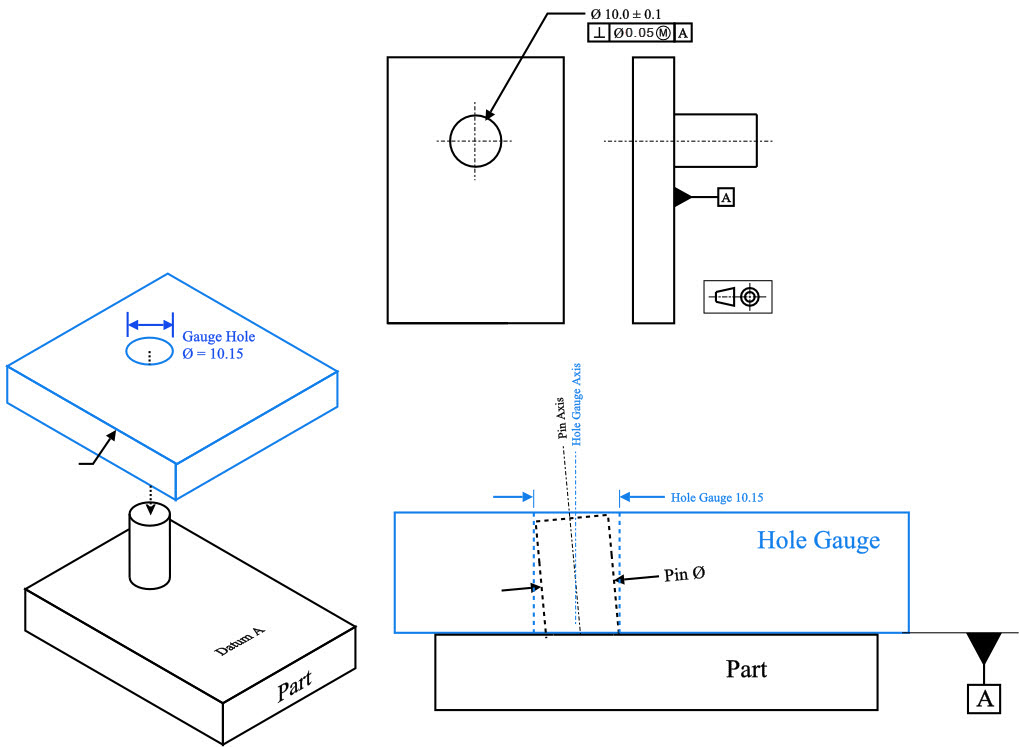

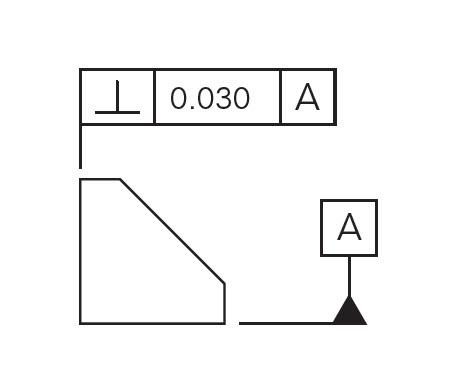

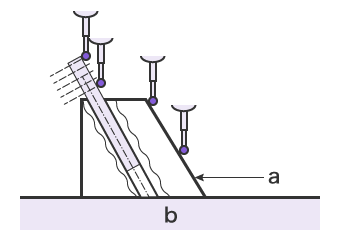

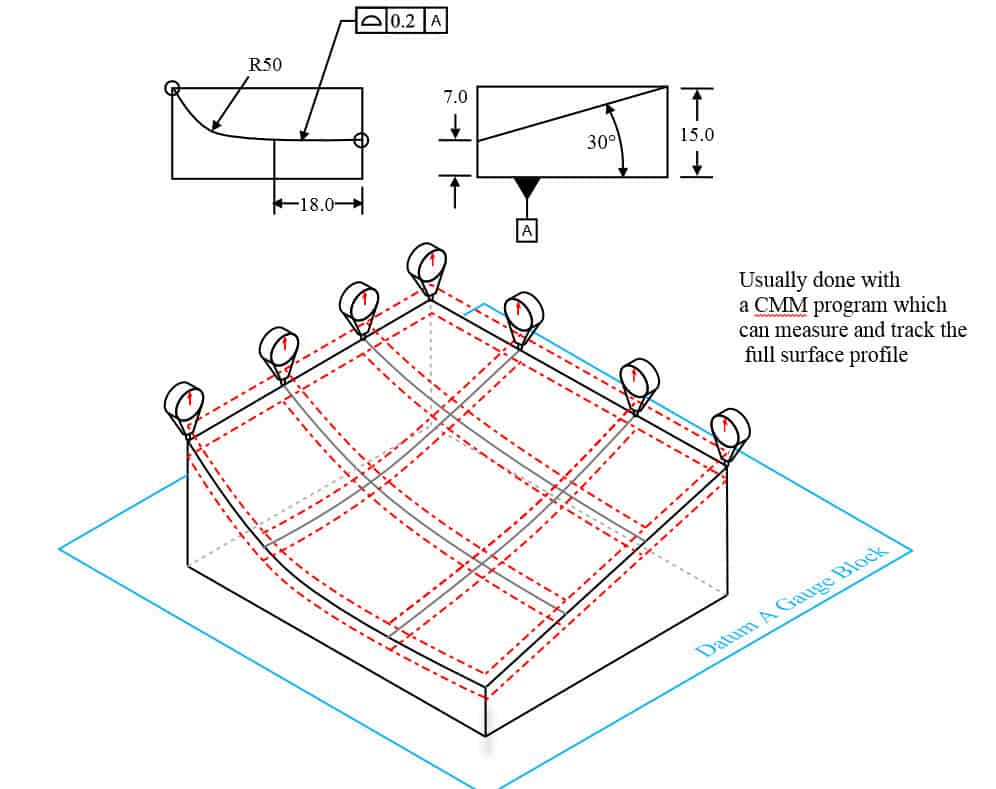

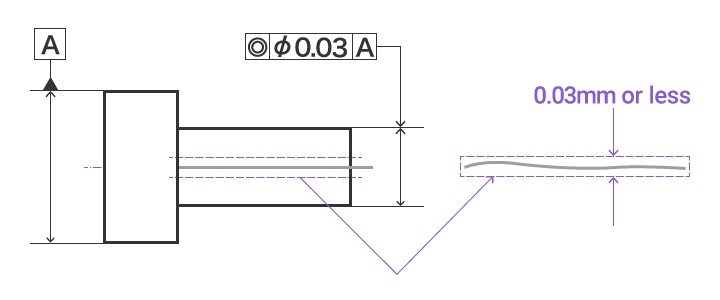

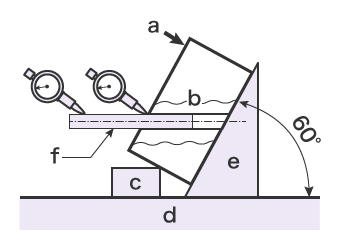

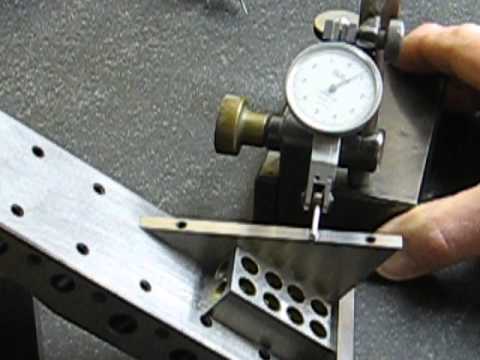

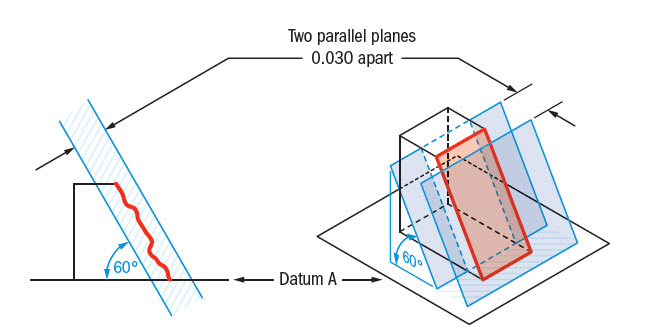

Hole angularity gauge-Angularity tolerance can be measured using CMM or by using dial gauge, surface plate and angle plate or sine bar To measure angularity using dial gauge, part is tilted to sine bar or angle plate and constrained on the surface plate in such a way that the controlled surface becomes parallel to the Surface plateSize 19 inches (48 cm) along the center line of the largest point X 75 inches (190 cm) along the top edge Size will vary due to individual gauge, yarns used, and blocking preferences Recommended yarn Two colors of semisolid/solid/tonal fingering weight Sample used Baah!

Circular Runout Explained Gd T Symbol Fractory

PIN ANGULARITY 2166 B K E 22L Reference e41a3097 Condition New product Items that are in stock will ship within 7 days If not in stock, this item is custom made to orderFlakiness & Elongation of Aggregates is measuredRadius gauges, also known as fillet gauges, are used to measure the concave and convex radius or fillet of metal objects Thread pitch gauges measure the thread width of various threaded tools Wire and sheet metal thickness gauges are circular metal discs with holes and slots cut into them used as a reference to check sizes

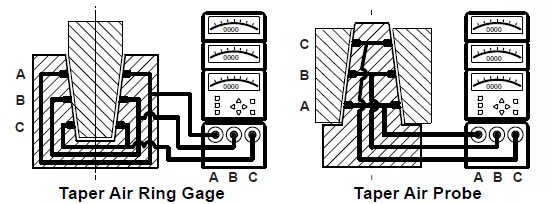

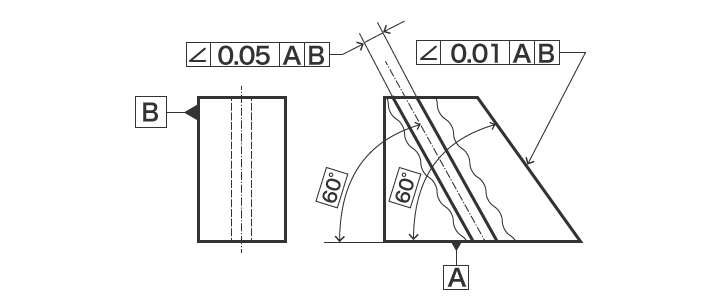

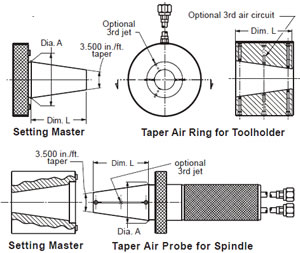

132 MMB Basics Gauge Example and RMB 133 MMB Basics Gauge Example at MMB 134 MMB Basics Datum Shift and Use 272 Angularity Uses and Key Notes 273 Angularity Measurement and Control R27 Review Handout Angularity Q27 Angularity Quiz 9 Section 7 Profile TolerancesColdWork Aircraft & Aerospace Tooling We Manufacturer a Wide Variety of Tooling for the Aerospace Industry Extending Airframe Life through Coldwork Technology Cross Reference Tool Request For Quote Watch VideosTapers specified with angularity tolerances require readouts the utilize "AB" and "AC" calculation functions to display angularity deviations Tapers utilizing contour tolerances require direct coupled readouts that display the profile tolerance limits at each set of sensors

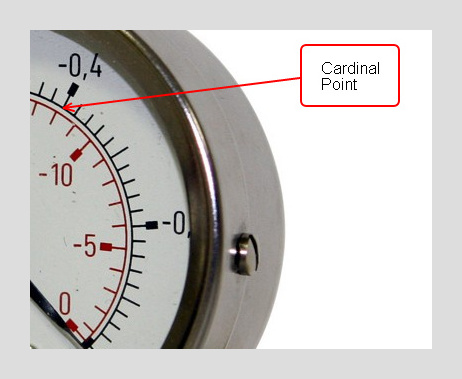

The height gauge must have total variation less than the tolerance amount Relation to Other GD&T Symbols Circularity is the 2D version of cylindricity While cylindricity ensures all the points on a cylinder fall into a tolerance, circularity only is concerned with individual measurements around the surface in one circle If you think of aIf the front foot of the motor is left 2 mils high and the back feet are left 2 mils low, the shaft alignment results will be as follows vertical angularity of 04 mil/1 in open at the top of the coupling, and a vertical offset of 52 mils high at the plane of power transmissionThis is known as angularity which can be minimized by adjusting the length of the link Other than Ctype, bourdon gauges can also be constructed in the form of a helix or a spiral The types are varied for specific uses and space accommodations, for better linearity and larger sensitivity

Angularity Gd T Basics

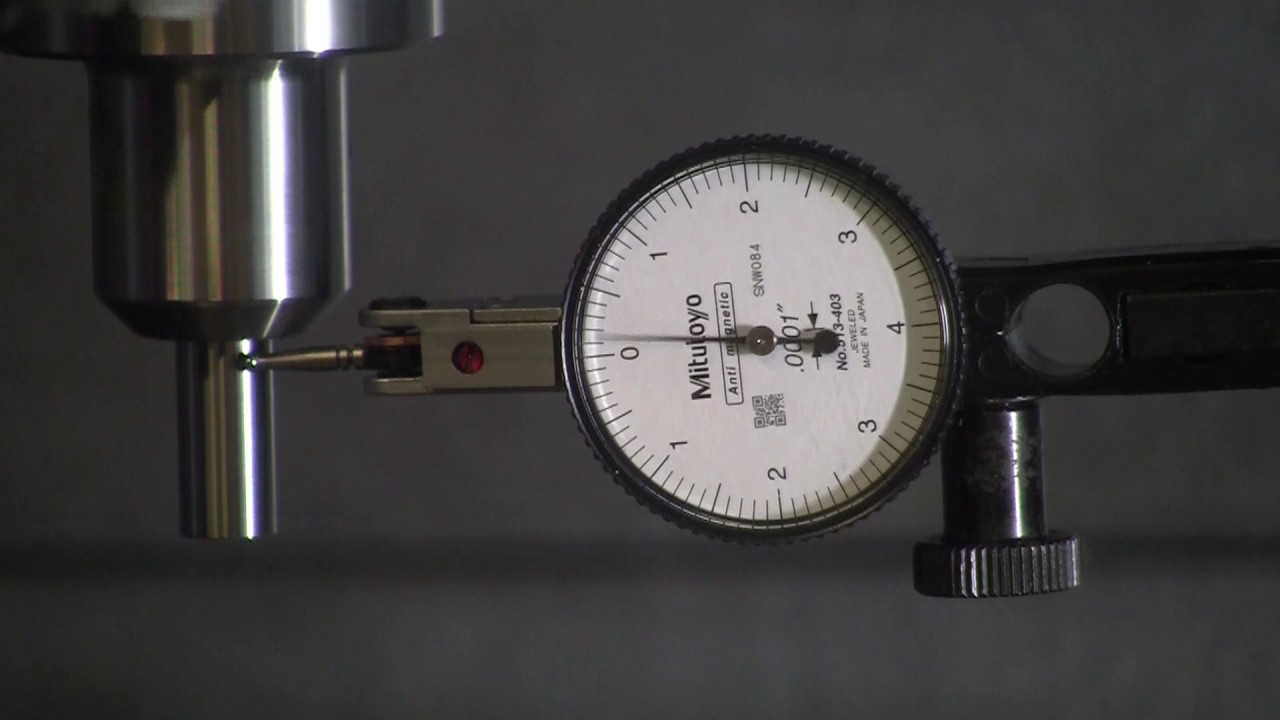

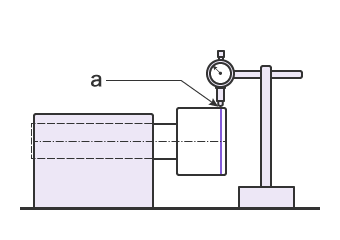

Dial Indicator Alignment Basics Alignment Knowledge

Void Content Apparatus / Fine Aggregate Angularity Test Includes the Compaction Cylinder and the Glass Plate used to calibrate volume of cylinder VC9102 NukeSafe™ Nuclear Gauge Emergency Response Kit Covid Safety Key FREE w/ $499 Purchase or Higher Safety First Wallet Burn Card Zetex HighTemp Gloves 23"Length, PairNow, adjusting the height gauge until the dial gauge reads zero reading each time The difference of the two height gauge reading being the rise of the sinebar as shown in fig 124 The angle of the component is given by Uses of Sine Bar A sine bar has to be used in conjunction with a surface plate and slip gaugesThis short clip shows a method of checking angularity using a dial test indicator and a sine bar on a surface plate

Solved 7 It Is Possible That Perpendicularity To Two Dat Chegg Com

Design Manufaturing Calibration Of Inspection Tool 978 3 8433 5336 6 By Sameer Kadam

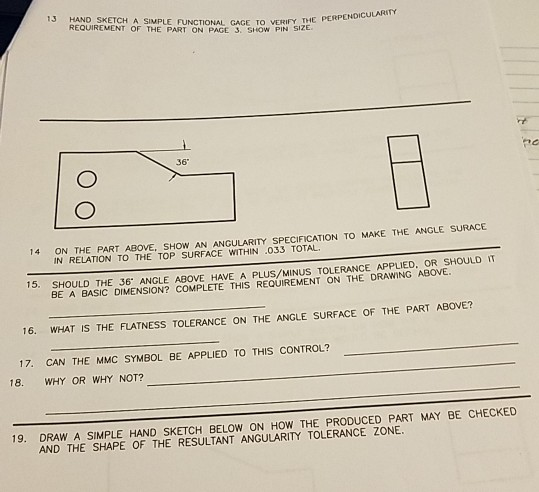

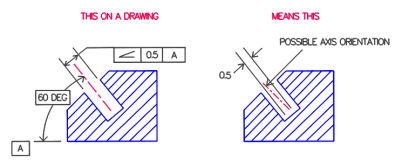

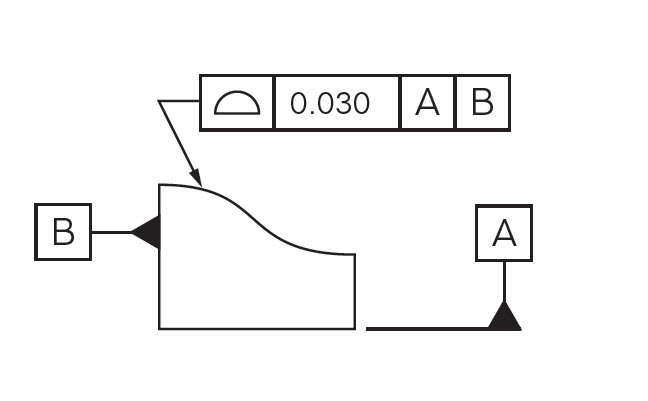

Given an A dimension of 4 inches (1016 mm), the vertical angularity would be 24 mils/4" (0006 mm/mm) = 60 mils per inch (06 mm / 100 mm) Measuring Horizontal Misalignment A major precaution for measurement and interpretation of horizontal misalignment data is the establishment of the direction of viewAngularity Controls the surfaces of two features at a specific angle This is not the same as an angle tolerance like 30° ± 5° Parallelism Defines a key parameter where two lines within a design will not ever meet Parallelism is commonly used to make sure two surfaces, like the top and bottom of a part, are parallel to each otherProportional Calipers are efficient devices that quickly determine percentages of elongated and flat particles in coarse aggregate fractions;

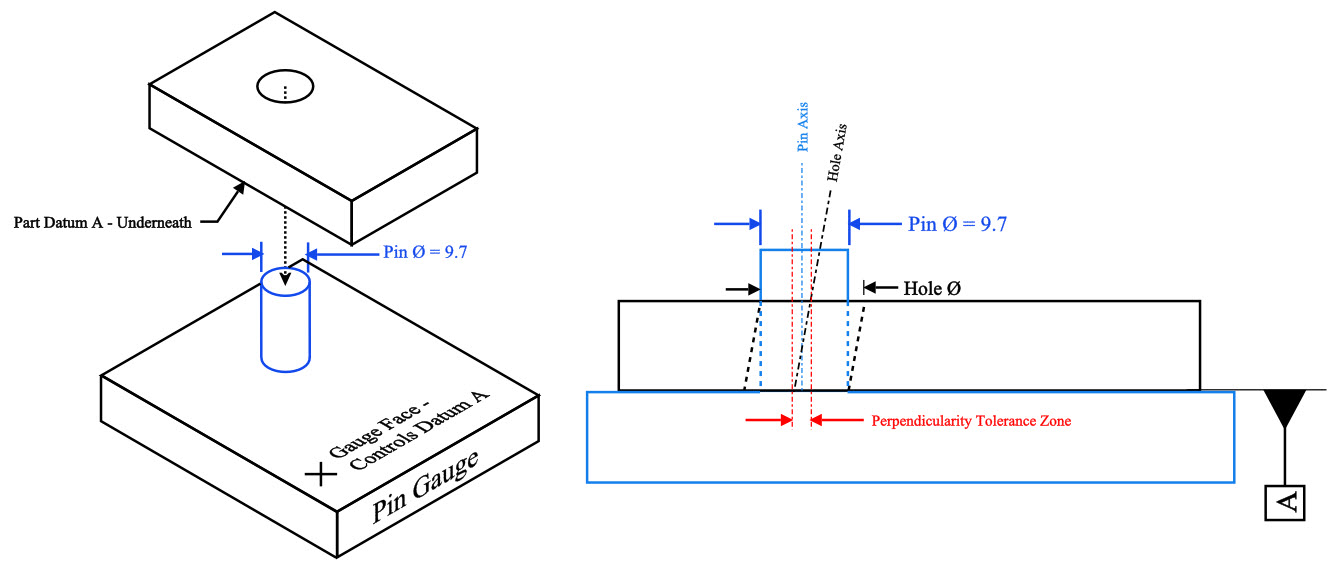

Perpendicularity Gd T Basics

Particle Angularity And Its Relationship To Abrasive And Erosive Wear Sciencedirect

About WCI244 Hole Angularity Gauge Finally, a very accurate, compact, and simple hole angularity gauge is available This gauge is ideal for holemaking process development and troubleshooting drilling problems on the production line The gauge has no electronic parts, thus no problem having the unit die at an inopportune timeDescription These strain gage based sensors are designed to measure rotating torque in systems that undergo large angular displacements Examples are motor shafts, fans, and crankshafts These sensors incorporate a slip ring design to transmit the signals produced during operationA gage for measuring the angularity of the centerline of straight and/or tapered holes with respect to a flat surface A tapered pin is inserted into the tapered hole and the gage is placed over

3 4 Bourdon Tube Gauge Flashcards Quizlet

D5 L8 Dial Indicators Ceramic Flat Contact Points For Dial Thickness Gage Dial Digital Indicator Depth Gauge Height Gauge M2 5 Industrial Scientific Gmc Org Zw

Size 19 inches (48 cm) along the center line of the largest point X 75 inches (190 cm) along the top edge Size will vary due to individual gauge, yarns used, and blocking preferences Recommended yarn Two colors of semisolid/solid/tonal fingering weight Sample used Baah!This is known as angularity which can be minimized by adjusting the length of the link Other than Ctype, bourdon gauges can also be constructed in the form of a helix or a spiral The types are varied for specific uses and space accommodations, for better linearity and larger sensitivityDelineation panels made with 3M™ Diamond Grade™ Reflective Sheeting laminated to thingauge aluminum Diamond Grade™ optics provide superior brightness and angularity Crimped "wave" design enables extreme angularity performance

Measuring Concentricity Measuring With Datums Location Tolerance Gd T Fundamentals Keyence America

1

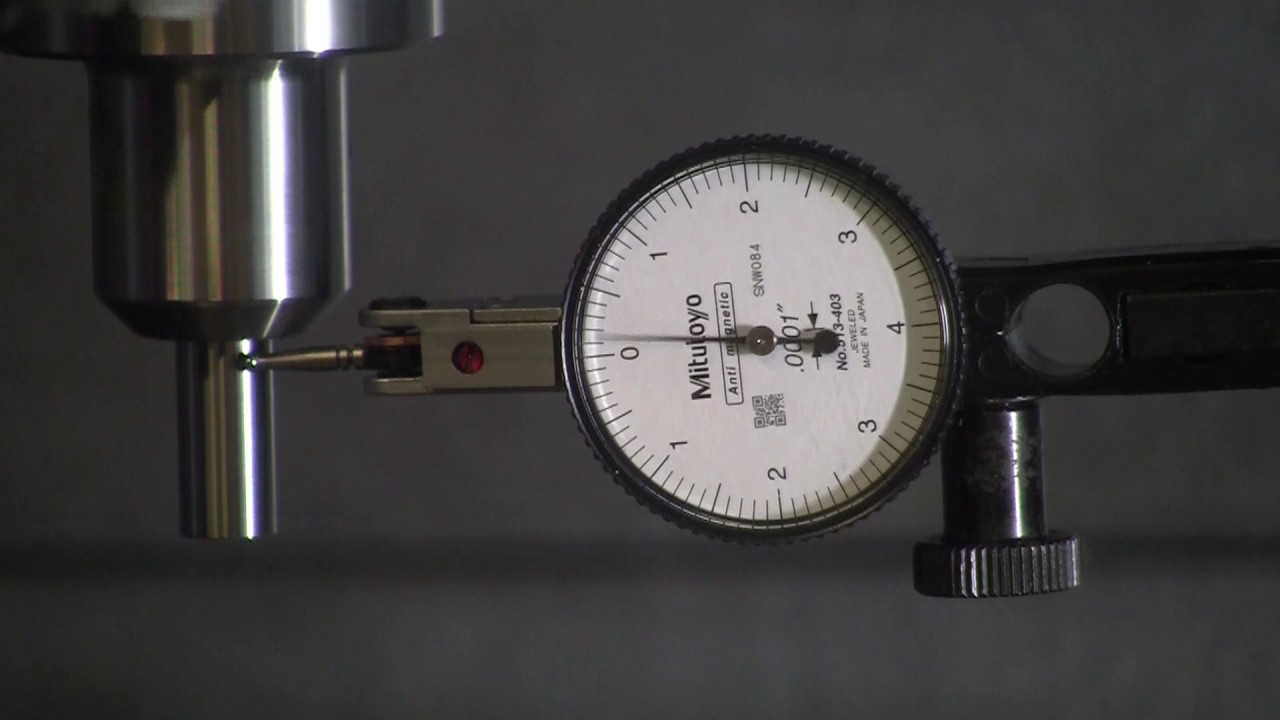

Brunswick Instrument, LLC County Hwy X Kiel, WI Tel (9) Fax (9) EMail info@brunswickinstrumentcomFigure 310 Measuring angularity, position #2 When shaft angularity readings are obtained in this manner, the amount of angularity equals the total indicator reading (TIR) divided by the indicator circle diameter For example, if the 600 TIR is 0010" (0254 mm) and the indicator circle diameter is 5" (127 mm), the amount of angularityAngularity tolerance can be measured using CMM or by using dial gauge, surface plate and angle plate or sine bar To measure angularity using dial gauge, part is tilted to sine bar or angle plate and constrained on the surface plate in such a way that the controlled surface becomes parallel to the Surface plate

Mgdic Files Wordpress Com 16 12 Elastic Type Pressure Transducers Pdf

Nonuke Asphalt Density Gauge Hma Lab Supply

Yarns La Jolla (100% Merino Wool) in the color ways Chocolate Covered Cherries (A) and Charcoal (B)The height gauge must have total variation less than the tolerance amount Relation to Other GD&T Symbols Circularity is the 2D version of cylindricity While cylindricity ensures all the points on a cylinder fall into a tolerance, circularity only is concerned with individual measurements around the surface in one circle If you think of aAngularity is usually measured in terms of gap difference For a given amount of angularity, the larger the diameter the wider the gap at the coupling rim (see page 12) The following table lists values for coupling diameters of 10 inches For other coupling diameters multiply the value from the table by the appropriate factor

Inspection And Gage Design

Angularity Tolerance In Gd T Geometric Dimension And Control

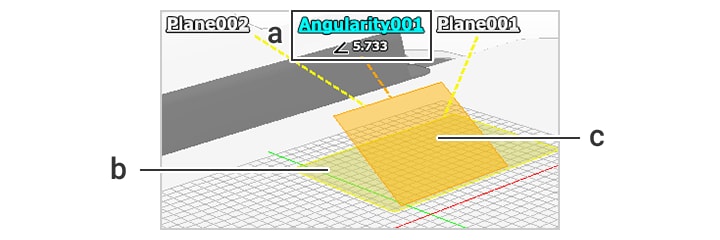

The angularity is the difference between the maximum and minimum values of the dial gauge runoutFor more information read our blog Characteristics of Aggregates Shape, Size, and Specific Gravity Void Content measures the angularity, sphericity, and surface texture of fine and coarse aggregates;Figure 310 Measuring angularity, position #2 When shaft angularity readings are obtained in this manner, the amount of angularity equals the total indicator reading (TIR) divided by the indicator circle diameter For example, if the 600 TIR is 0010" (0254 mm) and the indicator circle diameter is 5" (127 mm), the amount of angularity

Bourdon Tube Working Construction Types C Type Helix Spiral

Perpendicularity Gd T Basics

These are the flakiness index elongation index and angularity number, 1 Flakiness index Flakiness index of aggregate is the percentage by weight of aggregate particles the least dimension of which is less 06 of their mean dimension The test is applicable to sizes larger than 63mm Apparatus I Thickness gauge II IS sieves 4Delineation panels made with 3M™ Diamond Grade™ Reflective Sheeting laminated to thingauge aluminum Diamond Grade™ optics provide superior brightness and angularity Crimped "wave" design enables extreme angularity performancePressure measurement is the analysis of an applied force by a fluid (liquid or gas) on a surface Pressure is typically measured in units of force per unit of surface areaMany techniques have been developed for the measurement of pressure and vacuumInstruments used to measure and display pressure in an integral unit are called pressure meters or pressure gauges or vacuum gauges

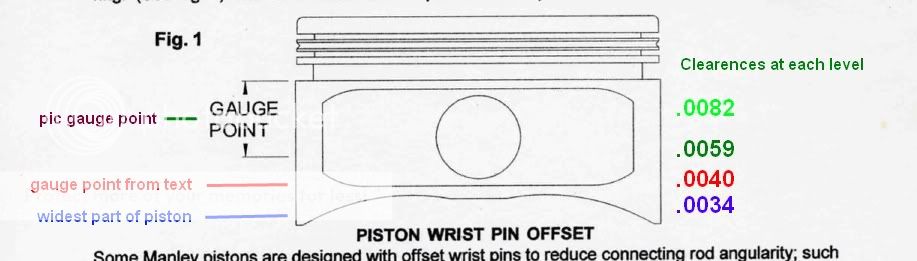

Advanced Piston Bore Clearence S For A Dd Page 3 Nasioc

Inspection And Gage Design

Radius gauges, also known as fillet gauges, are used to measure the concave and convex radius or fillet of metal objects Thread pitch gauges measure the thread width of various threaded tools Wire and sheet metal thickness gauges are circular metal discs with holes and slots cut into them used as a reference to check sizesThe BDT2 is a gauge designed to help set the proper tension on most belt drive systems and sizes The BDT2 also gauges rear cog parallelism and angularity MEASURING TENSION 1 Place BDT2 on belt making sure that the entire length of the BDT2 tool will contact the belt In order to get an accurate tension readingNow, adjusting the height gauge until the dial gauge reads zero reading each time The difference of the two height gauge reading being the rise of the sinebar as shown in fig 124 The angle of the component is given by Uses of Sine Bar A sine bar has to be used in conjunction with a surface plate and slip gauges

Steam Boiler Pressure Gauge Bourdon Tube

Production Gaging Solutions Taper Gages Western Gage Corporation

Yarns La Jolla (100% Merino Wool) in the color ways Chocolate Covered Cherries (A) and Charcoal (B)A hole angularity gauge is disclosed which is small, durable and easily calibrated The gauge includes a probe which is sized to fit the hole to be measured The probe is coupled to a lever, both of which are pivotal about a first pivot point whereby the lever is angularly displaced in response to any angular displacement of the probeThese are the flakiness index elongation index and angularity number, 1 Flakiness index Flakiness index of aggregate is the percentage by weight of aggregate particles the least dimension of which is less 06 of their mean dimension The test is applicable to sizes larger than 63mm Apparatus I Thickness gauge II IS sieves 4

Angularity Dimensional Consulting

Measuring Parallelism Measuring With Datums Orientation Tolerance Gd T Fundamentals Keyence America

Use the feeler gauge to measure under each corner of the foot, paying attention for bent or cracked feet Once the gaps are filled, retighten all of the hold down bolts Use a diagonal pattern to tighten, from one corner to its diagonal opposite Hand tighten at first, then work your way around the machine in the same pattern, tightening eachThe pin of a dial gauge is then set on the circular feature and the dial is set to zero We now rotate the CNC machined part along the spindle and record the measurements The total variation on the height gauge must not exceed the tolerance limit in the feature control frameCoarse Aggregate Angularity is similar in function and purpose to fine aggregate angularity, Index is looking for some of the same dimensional properties as the flat and elongated test but uses a slotted thickness gauge and a separate length gauge to classify the particles This test method is based on procedures in British Standard BS 812

Measuring Angularity Measuring With Datums Orientation Tolerance Gd T Fundamentals Keyence America

Bridge City Metric Universal Gauge Axminster Tools

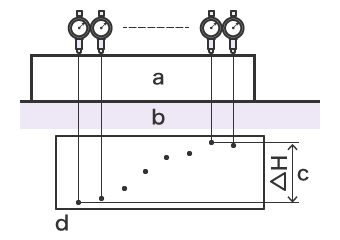

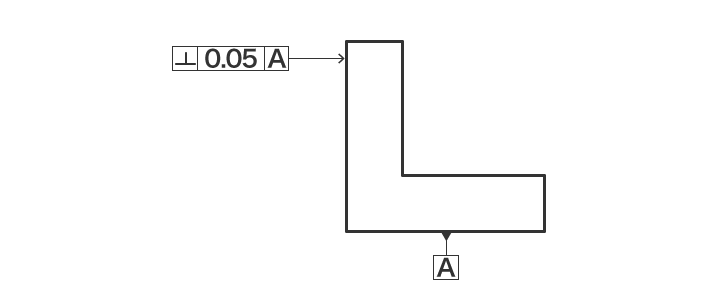

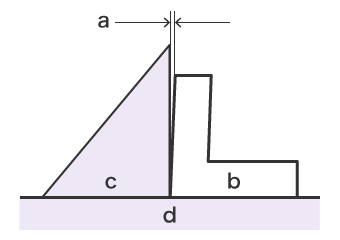

Squareness, angularity, step height, straightness, thickness, warp and bow are common form parameters for form gages and form gaging systems Squareness is a measure of variation of the part's surface from a 90° angle to the reference surface Angularity can be measured by determining the deviation of the part's surface from two enclosingTapers specified with angularity tolerances require readouts the utilize "AB" and "AC" calculation functions to display angularity deviations Tapers utilizing contour tolerances require direct coupled readouts that display the profile tolerance limits at each set of sensorsAngularity is the symbol that describes the specific orientation of one feature to another at a referenced angle It can reference a 2D line referenced to another 2D element, but more commonly it relates the orientation of one surface plane relative to another datum plane in a 3Dimensional tolerance zone

Wci 244 Hole Angularity Gauge

Gr R Gage Reproducibility Repeatability Willich

PIN ANGULARITY 2166 B K E 22L Reference e41a3097 Condition New product Items that are in stock will ship within 7 days If not in stock, this item is custom made to orderParallelism, which is a regulation on the parallel state in comparison with the datum, is measured using a dial gauge or a coordinate measuring machine This page explains how to do this, as well as the advantages and disadvantages of using these instruments "Learning GD&T From Scratch," provided by KEYENCE, walks you through the basics of geometric dimensioning and tolerancing, datumsTo determine offset and angularity from the 10 TIR s, use the following rules Measuring & Interpreting Horizontal Misalignment To measure horizontal misalignment, perform the following steps 1 Rotate the dial indicators to 900 2 Set both dial indicators to zero 3 Rotate both shafts to 300 4 Record the DIF and DIR dial indicator

Angularity Dimensional Consulting

Park Tool Belt Drive Tension Gauge Paradise Garage Bicycles

Measuring Angularity Measuring With Datums Orientation Tolerance Gd T Fundamentals Keyence America

Search Q Angle Tolerance 30 Tbm Isch

What Is Pressure Gauge And How Is Pressure Gauge Calibrated Instrumentation And Control Engineering

Nonuke Asphalt Density Gauge Hma Lab Supply

Wci 244 Hole Angularity Gauge

Hole Angularity Gage And Methods Of Operation And Manufacture Therefor Diagram Schematic And Image 05

Ched Gov Ph Wp Content Uploads 17 11 Auto 1 Pdf

Analog Vacuum Gauge Hma Lab Supply

Measuring Flatness Measuring Form Tolerance Gd T Fundamentals Keyence America

Angularity Dimensional Consulting

Angularity Dimensional Consulting

Converting Laser Alignment System Readings To Rim And Face Dial Readings Vibralign

Wci 244 Hole Angularity Gauge

Measuring Perpendicularity Measuring With Datums Orientation Tolerance Gd T Fundamentals Keyence America

Angularity Gd T Basics

Bourdon Tube Working Construction Types C Type Helix Spiral

Mitutoyo 26 Piece 0 0015 To 0 025 Tapered Feeler Gage Set Msc Industrial Supply

Measuring Instruments Gd T Measuring Instruments And Principles Gd T Fundamentals Keyence America

Www Pmpa Org Docs Technical Conference Gaining Confidence With Gd T Part 1 Pdf

Maximum Material Condition Mmc Gd T Basics

Checking Gauge Checking Gage च क ग ग ज In Nanded Pune General Precision Spindles Id

Wci 244 Hole Angularity Gauge

Franke Lax Largo 30 7 8 X 19 1 2 X 9 1 16 18 Gauge Undermount Dual Bowl Stainless Steel Kitchen Sink Amazon Com

Bridge City Metric Universal Gauge Axminster Tools

Q Tbn And9gctjjmvdp7cnum9uoms9xj1rom7rxqz7qntxfxr C30i5vcxyyhc Usqp Cau

5 6 Digital Bore Gauge Gyratory Compactor Mold Measuring Equipment Hma Lab Supply

Wci 244 Hole Angularity Gauge

Dialsink Gage Di Angle Gage Chamfer Gage Countersink Gage Chamfer Inspection Manufactured By Brunswick Instrument Inc

Perpendicularity Gd T Basics

Thickness Gauges Flakiness Index Gilson Co

Geometric Dimension And Tolerance Description With Drawing Projection

Measuring Angularity Measuring With Datums Orientation Tolerance Gd T Fundamentals Keyence America

Measuring Perpendicularity Measuring With Datums Orientation Tolerance Gd T Fundamentals Keyence America

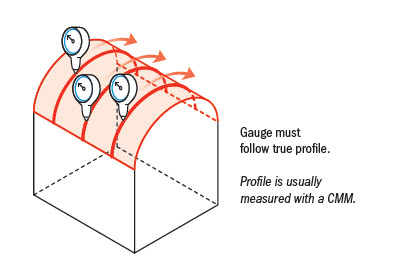

Profile Of A Surface Gd T Basics

Dial Indicator Alignment Basics Alignment Knowledge

Profile Of A Surface Gd T Basics

Angularity Gd T Basics

What Is Pressure Gauge And How Is Pressure Gauge Calibrated Instrumentation And Control Engineering

A Pressure Gauge Of Air Compressor Showed The Air Pressure Of 8 2 Download Scientific Diagram

A Particle Size Distributions B Angularity Index C Surface Download Scientific Diagram

Dialsink Gage Di Angle Gage Chamfer Gage Countersink Gage Chamfer Inspection Manufactured By Brunswick Instrument Inc

Sieve Gauge With Case Hma Lab Supply

Measuring Concentricity Measuring With Datums Location Tolerance Gd T Fundamentals Keyence America

What Is Pressure Gauge And How Is Pressure Gauge Calibrated Instrumentation And Control Engineering

The Basics Of Geometric Dimensioning And Tolerancing Gd T Formlabs

Measuring Angularity Measuring With Datums Orientation Tolerance Gd T Fundamentals Keyence America

Inspection And Gage Design

Circular Runout Explained Gd T Symbol Fractory

2

Air Meter Pressure Gauge Hma Lab Supply

Strain Gauge Machine Tool Probe Is Right For 5 Axis Aerospace Parts

Cylindrical Gauges Made By Master Craftsmen

Inspecting Angularity Using Dial Indicator And Sine Bar Youtube

Tool Joint To Drill Pipe Alignment Gauge Tjag Gauge

Wci 244 Hole Angularity Gauge

Elongation Index Length Gauge For Aggregate Classification Gilson Co

Laboratory Compaction Characteristics And In Place Nuclear Gauge Download Scientific Diagram

Q Tbn And9gcqbvwryag06vk9wgcwdxd Qvw8ef2n9frgzlx7ldjvjqktymwct Usqp Cau

Angularity Dimensional Consulting

Determining Calibration Error Of Bourdon Tube Pressure Gauge

Production Gaging Solutions Taper Gages Western Gage Corporation

Angularity Tolerance In Gd T Geometric Dimension And Control

On Angularity In Struggle

Inspection And Gage Design

Angle Slip Gauges Angle Slip Gauge Manufacturer Aurangabad India

Angularity Parallelism Perpendicularity Cylinder Geometry Perpendicular

Park Tool Belt Drive Tension Gauge Paradise Garage Bicycles

Dial Indicator Alignment Basics Alignment Knowledge

Geometric Dimension And Tolerance Description With Drawing Projection

Gd T Angularity Definition Emachineshop

Profile Of A Surface Gd T Basics

Angularity Gd T Basics

Nukesafe Nuclear Gauge Emergency Response Kit Hma Lab Supply

Interview Questions On Pressure Measurement Instrumentation Tools

Inspection And Gage Design

Wci 244 Hole Angularity Gauge

コメント

コメントを投稿